IRIS™ Camera Positioning System

Overhead cameras provide accurate drag-and-drop artwork placement.

What makes artwork placement with an Epilog Laser so easy?

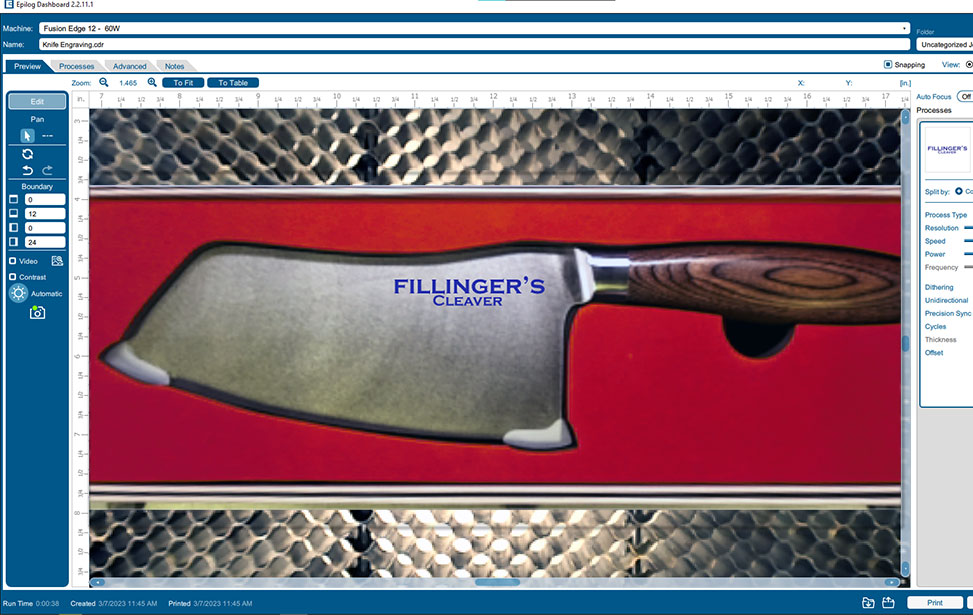

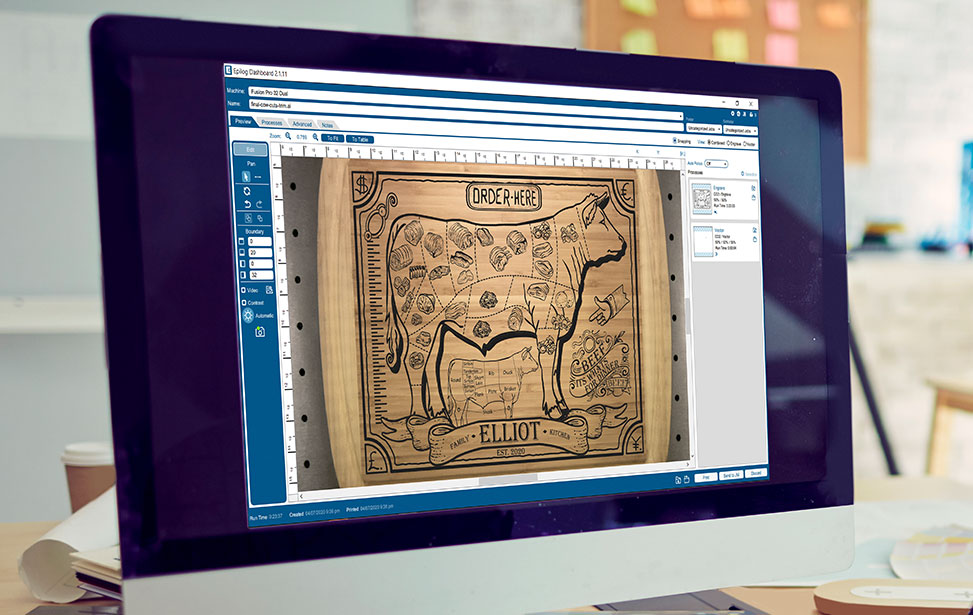

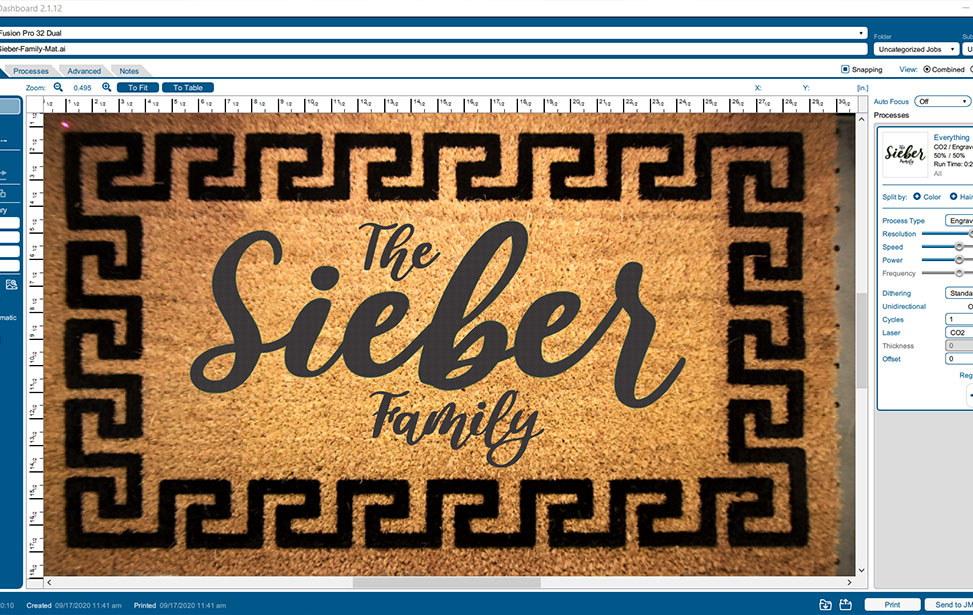

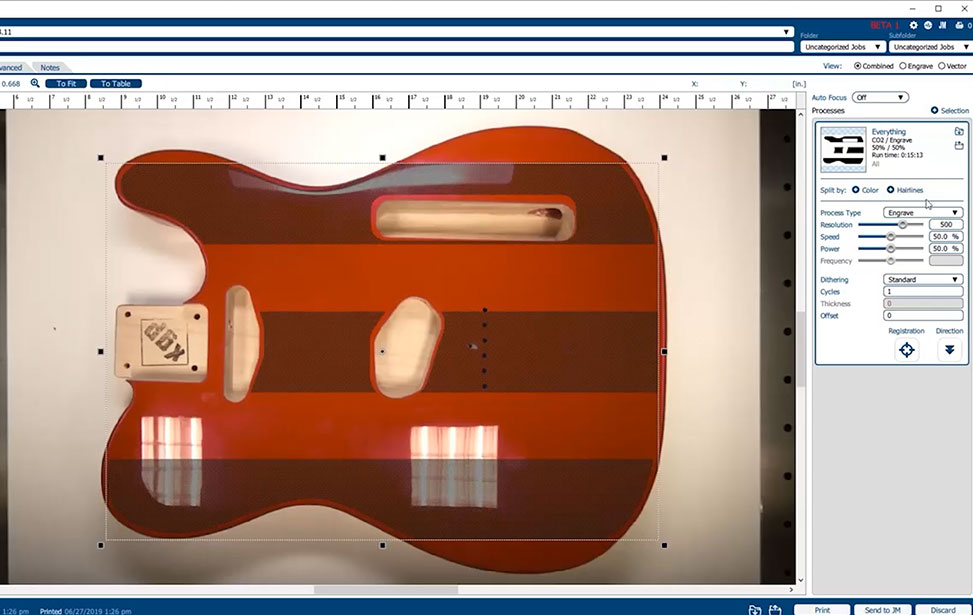

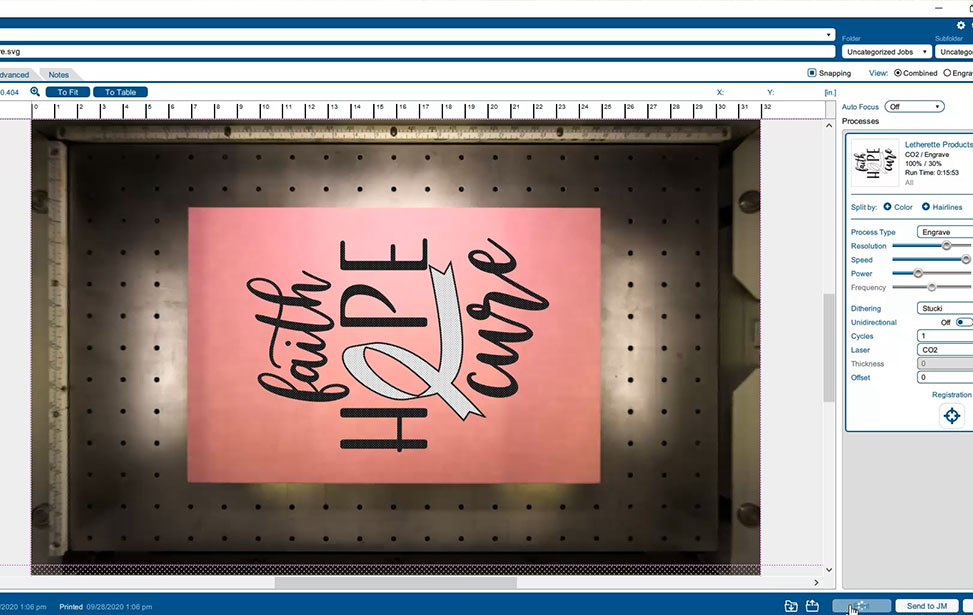

It’s our IRIS™ Camera Positioning System that is revolutionizing the way you work with our laser machines. With our sophisticated technology, you can place your artwork for engraving and cutting more quickly and accurately than ever before. The included overhead cameras provide an accurate live view of any material you place on the laser’s work surface. This allows you to drag and drop your artwork directly onto your sheet material, part, or product, giving you greater control and faster turnaround times. In other words, it makes bringing your laser projects, products, and creations to life quick, easy, and more fun!

Aligning Your Laser Projects Is Easier Than Ever

What You See Is Where You Engrave

The IRIS Camera Positioning System increases accuracy when placing the artwork by providing a “what-you-see-is-where-you-engrave” experience. Instead of manually measuring distances or using old trial-and-error techniques, the camera allows you to precisely position artwork and ensure accurate engravings and cuts every time. Our advanced camera features help reduce the number of mistakes made during production, resulting in less material waste, better quality products, increased production, and improved workflow efficiency overall.

IRIS™ Camera System Feature Comparison

| Fusion Maker 12 |

Fusion Edge 12/24/36 |

Fusion Pro 24/36/48 |

Fusion Galvo G100 |

|

|---|---|---|---|---|

| IRIS™ Camera Positioning

1 or 2 Overhead Cameras |

||||

| IRIS™ Camera Registration

1 Lens Assembly Camera |

How-to Print, Position, and Laser Engrave

with Epilog’s IRIS Camera Positioning System

1. Print to the Epilog Laser Dashboard

2. Drag & Drop the Artwork into Position

3. Select Material Settings and Laser It!

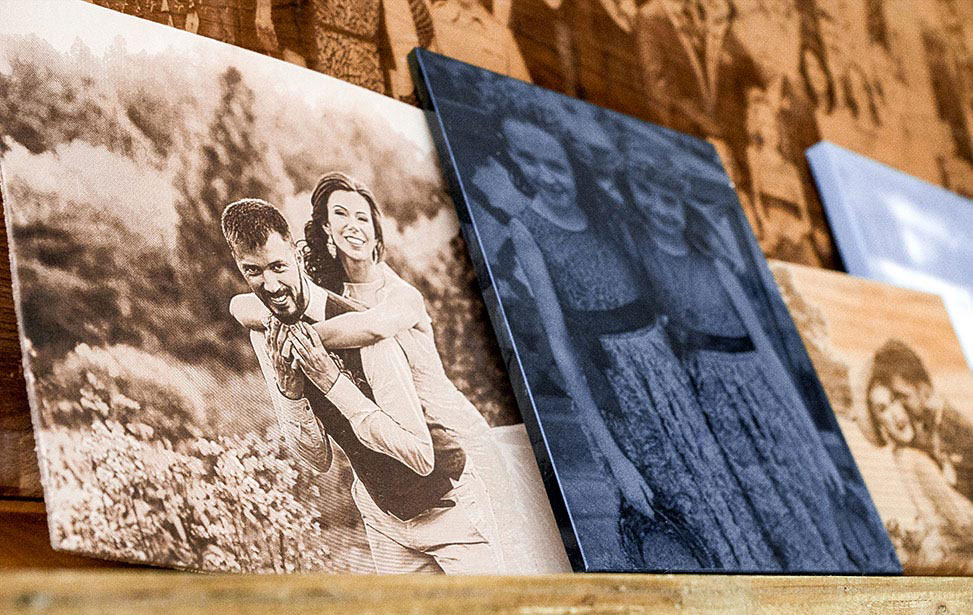

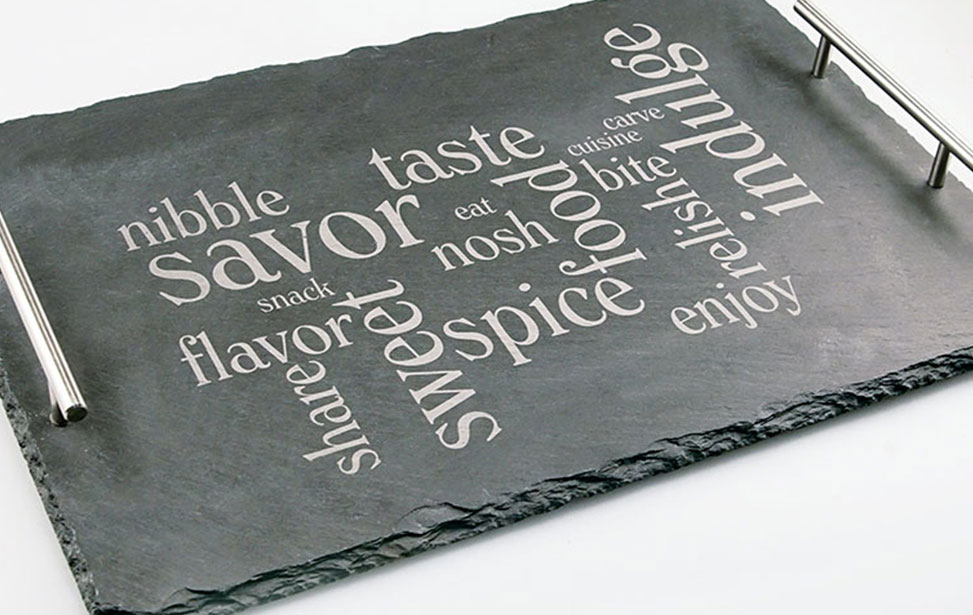

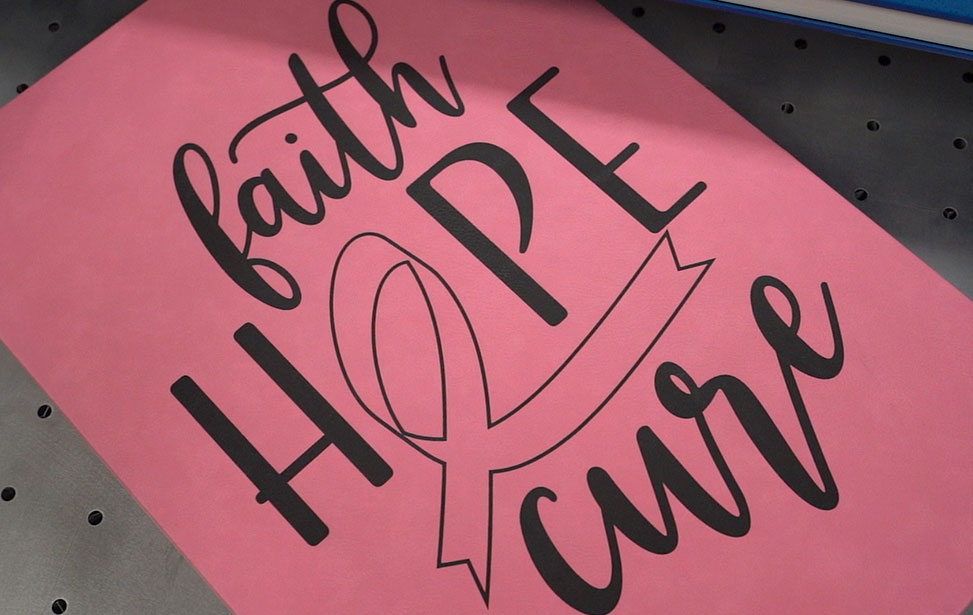

What Can You Create?

Top 10 Advantages of a Live-Preview Camera

Positioning System in Your Laser

Live-Preview Camera Workflow Assist

- Increased precision and accuracy for placing designs, logos, and serial numbers on products and materials

- Faster proofing and production time with drag-and-drop & resizing features

- Improved quality assurance for customers

- Easier and quicker setup improves run-time estimates for customer quotes

- Modernized workflow monitoring of parts for compliance and conformance to customer specifications

Laser Business Efficiency & Service Profitability

- Reduced material waste with the reduction of mistakes made during production testing, research, and development

- Lower material costs through scrap material reuse

- Ability to create “just in time” laser engravings for one-off personalized project requests

- Reduction in labor costs due to the simplification of set-up processes and increased speed of processing times

- Improved safety for laser users through fewer material and machine-touch operations

Fusion Pro Power Up for Your IRIS Camera System

Add a Registration Camera for Laser Die Cutting

Our Fusion Pro lasers include an additional camera at the lens assembly for the precise laser die-cutting and finishing of your digitally printed projects. Simply place the color-printed paper, wood, or acrylic project, with included registration marks, onto the laser worksurface, then let the Epilog Dashboard Software and the Fusion Pro do the rest.

With ease of use as our goal, the Fusion Pro IRIS Camera die-cutting features help businesses meet deadlines, streamline laser-finishing workflows, expand product offerings, and increase profits across the business.

Power Your Future with the Fusion Pro

If you’re looking for a laser to create real products that you can sell, you will quickly discover that the investment in a professional-grade laser system from Epilog will help you succeed. The Fusion Pro reflects 30+ years of laser design and manufacturing experience, combining time-tested mechanics with modern features and conveniences. Our customers have found great success using Epilog Laser machines to build and expand their businesses and make their dreams a reality. Fill out this form, and let’s discuss what ideas you have for a laser system.

Accomplish More with IRIS Camera Positioning

Time Is Money For Laser Businesses

Request More Information

and get more info from your local distributor.