Fusion Galvo Laser Series

High-speed marking with sophisticated camera technology.

Fusion Galvo G100

Metal Marking Machine

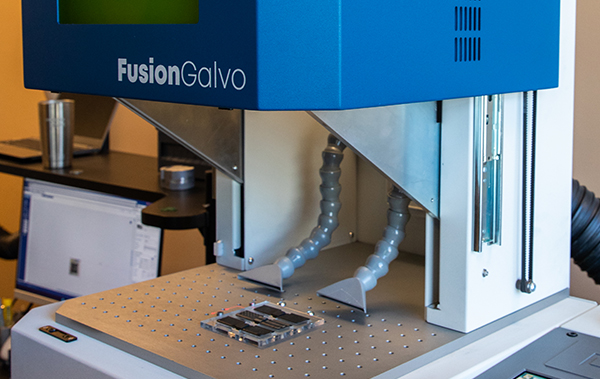

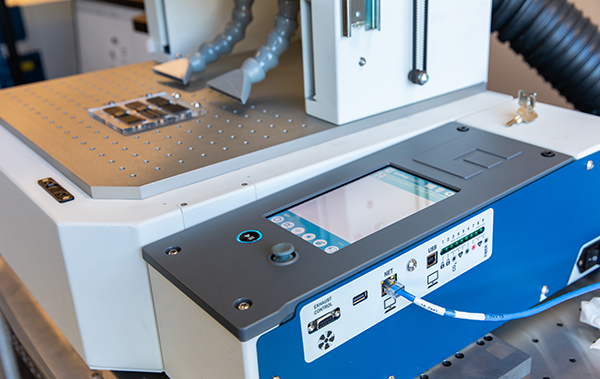

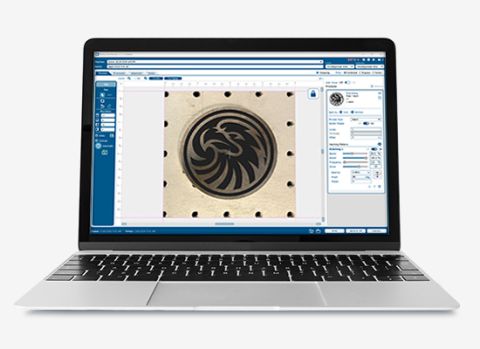

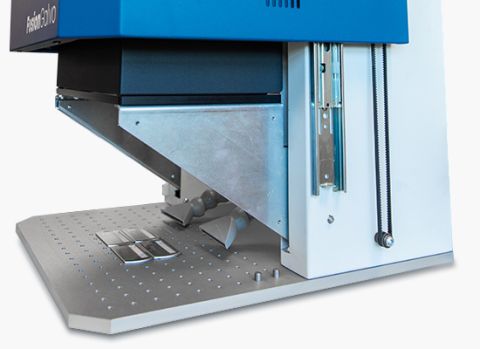

The Fusion Galvo by Epilog Laser combines fast engraving of metals with quick and efficient project setup. This innovative laser machine produces a variety of marks on metal, including deep engraving, polished white marks, and deep black annealed etching. Project setup is fast and easy using Epilog’s Laser Dashboard and artwork placement is exceptionally precise thanks to the IRIS™ camera system. The Fusion Galvo features an exceptionally user-friendly interface and uses high-quality parts and components, giving you unbeatable metal etching results.

CLOSER LOOK:

Request Free Samples and Pricing Information

"*" indicates required fields

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

| Laser Machine | Fusion Galvo G100 | |

|---|---|---|

| Included Lenses: | F163 and F254 lens | |

| Work Area: | F163: 4" x 4" (101 x 101 mm) F254: 6" x 6" (152 x 152 mm) |

|

| Material Thickness: | F163: 10" (254 mm) F254: 6" (152 mm) |

|

| Laser Tube Types: | Fiber, air-cooled, 1064nm | |

| Laser Tube Wattages: | 30-watt MOPA, 60-watt MOPA, or 100-watt MOPA fiber configurations | |

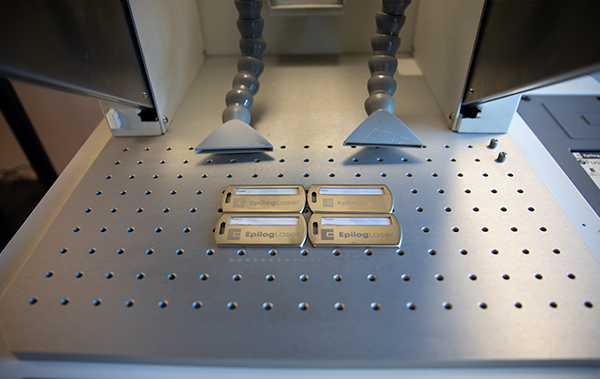

| IRIS™ Positioning Cameras: | 2 overhead | |

| More Tech Specs | ||

No Complicated Programming Involved

Two Lenses, Two Cameras, Two Field Choices

Automated Door for Quick Changing of Parts

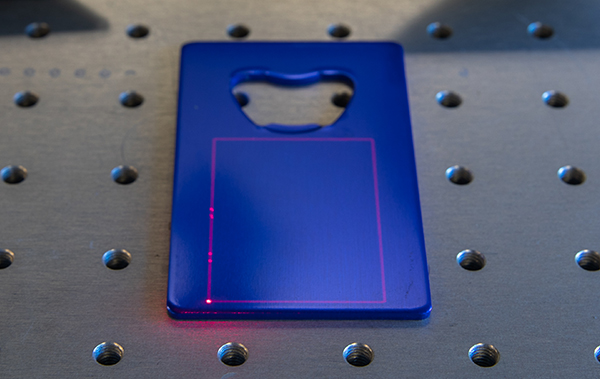

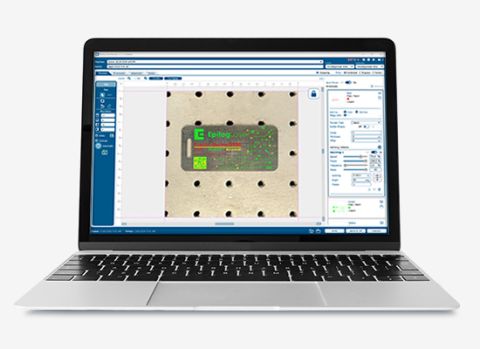

Accurate Camera Positioning of Your Artwork

Galvo Project Setup

FEATURES: Machine Enhancements Designed to Increase Productivity

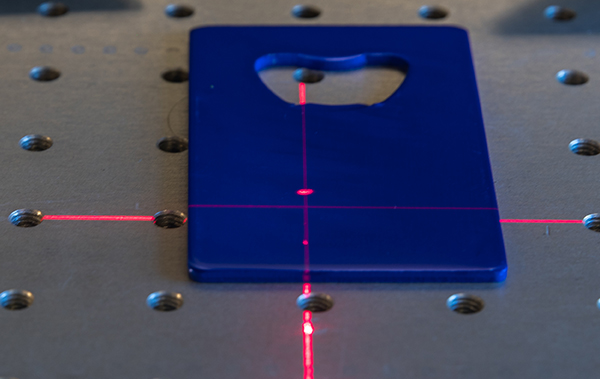

IRIS™ Camera Positioning

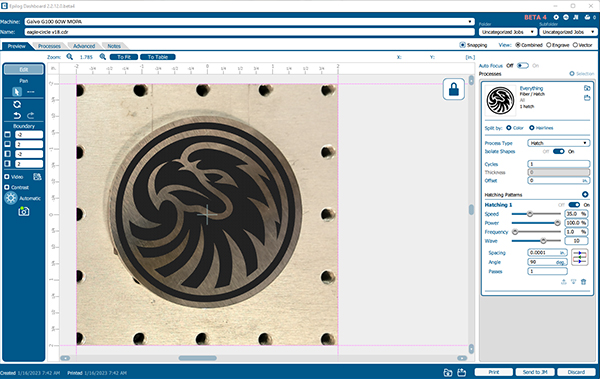

Learn MoreAn overhead camera system provides a real-time picture of the working area for accurate artwork placement. Drag and drop your graphics on screen for quick processing.

Learn More

PrintAPI

Process & Workflow Integration Learn MoreDesigned as a flexible library, PrintAPI empowers developers to seamlessly create and send print jobs to Epilog Laser machines directly from their own software environments.

Learn More

Epilog Pulse

Mac Compatible Learn MoreThe Pulse application is a multi-platform print application that can be used with Mac, Linux, other non-Windows operating systems, and Windows.

Learn MoreAccessory

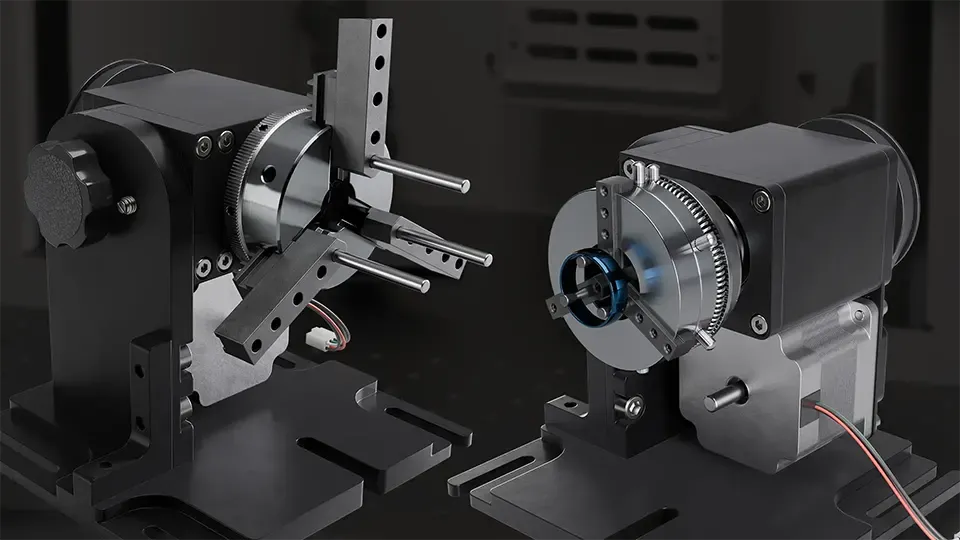

Galvo Rotary Attachment

The Rotary Attachment option for the Fusion Galvo G100 allows you to engrave cylindrical items like tumblers, rings, and tubes quickly and easily. The 3-Jaw-Chuck design of the rotary allows for maximum precision on a variety of common cylindrical products.

Shop Now

Two styles: Ring Head Jaw and 3-Jaw Chuck

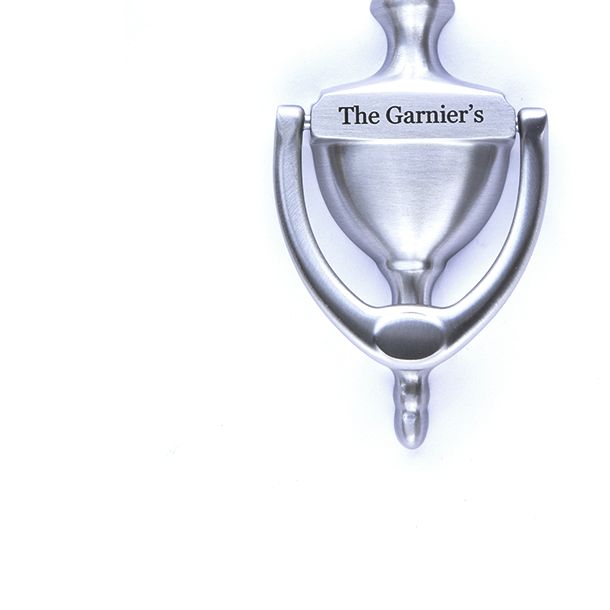

Endless Customization

Size Options

Compass Design

AR

Lower

Door

Knocker

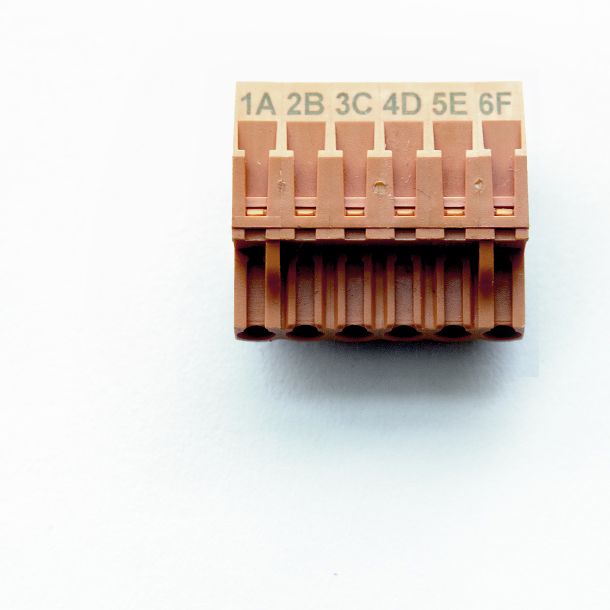

Connector

Clamps

AR

Lower

Clamps

Eagle Coin

Metal Ring

Dog Food Bowl

AR

Magazine

Wrench

Coaster

Material Compatibility:

With the Fusion Galvo, mark a wide array of metals and engineered plastics.

| 17-4 PH stainless steel | 303 stainless | 4043 steel | 6061 Aluminum |

| ABS (white/black) | Aluminum, 6061 | Aluminum, yellow chromate | Bayer 2807 Makrolon polycarbonate |

| Bayers bayblend FR110 | Black/white ABS | Black/white polycarbonate | Brass |

| Brushed aluminum | Carbon nanotube | Ceramics, metal-plated | Clear coat anodized aluminum |

| Cobalt chrome steel | Colored delrin (black/brown) | Compacted powder iron with phosphate coating | Copper |

| DAP – Diallyl Phthalate | Delrin, colored (black/brown) | GE Plastics polycarbonate resin 121-R | Glass filled PEEK |

| Glass filled Teflon | Hard coat anodized aluminum | Inconel metals (various) | Machine tool steel |

| Magnesium | Metal-plated ceramics | Molybdenum | Nickel plated 1215 mild steel |

| Nickel plated brass | Nickel plated gold | Nickel plated Kovar | Nickel plated steel |

| Nylon | PEEK, white | Polybutylene Terephthalate | Polycarbonate (black/white) |

| Polycarbonate resin 121-R, GE Plastics | Polycarbonate, Bayer 2807 Makrolon | Polysulphone | Rynite PET |

| Santoprene | Silicon carbide | Silicon steel | Silicone wafers |

| Stainless steel 303 | Stainless steel 17-4 PH | Steel 4043 | Steel, machine tool |

| Various inconel metals (nickel-chromium super alloys) | White PEEK | Yellow chromate aluminum | Zinc plated mild steel |

| And Many More! | |||

TECHNICAL SPECIFICATIONS: Fusion Galvo Laser Machines

Laser Machine: |

FUSION GALVOMetal Marking Machine

|

Work Area: |

F163: 4" x 4" (101 x 101 mm) F254: 6" x 6" (152 x 152 mm) |

Material Thickness: |

F163: 10" (254 mm) F254: 6" (152 mm) |

Laser Source: |

Fiber, air-cooled, 1064nm |

Laser Source Wattages: |

30-watt MOPA, 60-watt MOPA, or 100-watt MOPA fiber configurations |

IRIS™ Camera System: |

2 overhead |

Software Compatibility: |

Works with most Windows-based CAD and design software |

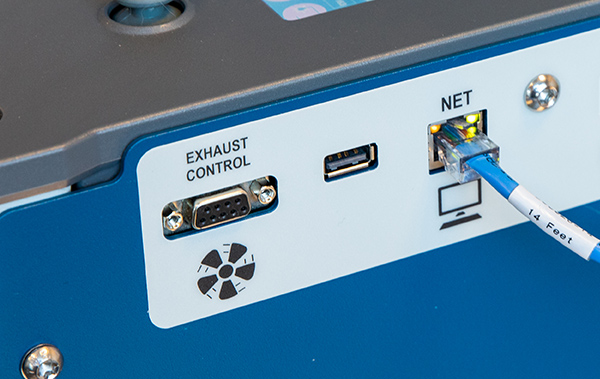

Wireless Connectivity: |

Included |

Included Lenses: |

F163 and F254 lens |

Resolution: |

Fully-flexible & user-controlled from 75 – 1200 dpi |

Print Driver & Software: |

Laser Dashboard™, Epilog Job Manager™ |

Internal Memory: |

Store multiple files up to 1 GB. Engrave any file size. |

Super-Silent Cooling Fans: |

Included |

Job Trace: |

Included |

Auto Focus: |

Included |

Touch Screen: |

Included |

Max Table Weight: |

100 lbs (46 kg) |

Size (W x D x H): |

28" x 23" x 31" (door closed) 37" height (door open) 711mm x 584mm x 787mm / 940mm |

Weight: |

131 lbs (59.5 kg) |

Electrical: |

Auto-switching 100-120 volts, Amp draw-MAX: 13A Auto-switching 220-240 volts, Amp draw-MAX: 6.5A 50 or 60 Hz, single phase |

Ventilation: |

450-650 CFM (764-1104 m3/hr) |

Class |

Class 2 Laser Product – 1 mW cW MAXIMUM 600-700nm |

Request More Information

Request More Information

and get more info from your local distributor.