What do I need to run my laser machine?

Know what software and equipment you’ll need to get up and running with your laser machine

Epilog’s laser equipment is designed to be exceptionally user friendly and you can easily get up and running with one of our machines. When you set up a laser system, there are a few other items you’ll need to make sure you have or you acquire. It’s important to understand what these items are so you can properly integrate them into your budget and workspace. Here we’ll look at what you need to successfully incorporate a laser machine into your current operation.

To get started with your laser machine, you’ll also need a computer, a graphics software program, an exhaust setup, and any machine accessories you choose.

Laser Machine

Laser cutting/engraving systems range from $8,995 to around $73,000 (U.S. pricing) based on the size of the engraving table and wattage of the laser. A higher-wattage machine engraves and cuts faster than a lower-wattage system, and a higher wattage also lets you cut through thicker materials. All lasers manufactured by Epilog are air-cooled so you don’t need a separate external water reservoir, hoses, or a recirculation pump.

Computer

You’ll need a computer so you can work with whichever graphics software you choose, as well as the Epilog Laser Software Suite from which you control your laser. From your computer, you will create and/or print your artwork, as well as configure the laser to achieve the cutting and engraving results you desire. All new Epilog systems are compatible with Windows 10/11. We recommend the following hardware specifications for laser applications.

RAM (Random Access Memory)

RAM determines how much your computer can do at any given time. More RAM generally equates to more efficiency. Most computers come with at least a couple gigabytes of RAM, but you’ll want to make sure you have at least 512 MB of RAM available to run laser-related software.

Processor Speed

The speed of your processor affects how smoothly your software operates. A faster processor will ensure your software performs well, allowing you to do more tasks in less time. Processor speeds are measured in gigahertz (GHz). You’ll need at least a 2.0 GHz processor.

Hard Drive

This is the permanent memory in your computer, where you’ll store your artwork files, as well as install your graphics software and the Epilog Laser Software Suite. How much space you require will depend on how many files you’re working with. Some users feel you can never have a large enough hard drive, but for most laser applications a 20 or 30 GB hard drive is going to be adequate for years of storage.

Mac / Tablet

Are you operating on a Mac OS? No worries. Thanks to Epilog’s Pulse Application, you can run our lasers with Macs, ipads, and other tablets. You just connect the laser to your device in one of three ways: Wi-Fi, Ethernet, or USB. Once you do that, simply open a web browser window, type in the IP address of the laser, and hit enter. The app loads automatically, and you can then import various files and send them to the laser for processing! Learn more about Epilog Pulse and get connection instructions here.

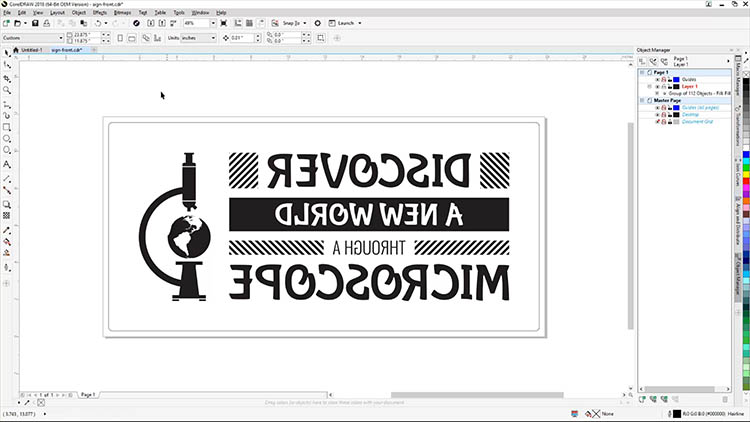

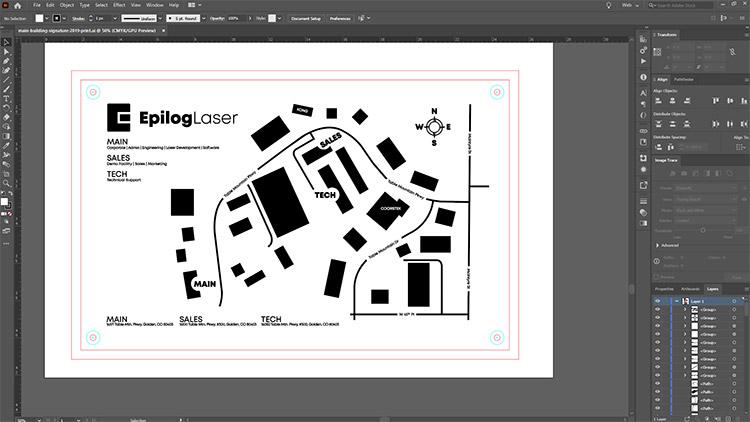

Graphics Software

When you work with your laser, you’ll be sending artwork to the machine by printing it from a graphics software program. Epilog has an open-architecture design, which means you aren’t locked into proprietary software and you can use nearly any Windows-based graphics program. Most Epilog Laser operators use CorelDRAW, but you could use Adobe Illustrator, AutoCAD, or another program you’re already familiar with.

Exhaust Fan

Cutting and engraving with a laser produces smoke and debris when the laser burns away the material you’re working with. To maintain the health and safety of the laser operator and those around them, it is mandatory that you exhaust the air from the system. The exhausted air can be vented to the outside or into a portable filtration system.

Exhaust Blower…

The simplest way to exhaust air from your laser is to connect an exhaust motor-blower via ducting. This blower will draw air out of the machine, then push the air out through ducting to wherever you direct it. A simple setup could guide the airflow directly to the outside, whereas some more sophisticated setups will connect the exhaust to a larger airflow system. Your approach will depend on your work area and budget. We recommend consulting an HVAC professional to determine how best to integrate an exhaust solution within your workspace, and to confirm you are compliant with local ordinances.

If you are unable to vent outdoors, you will need to purchase a portable filtration unit, which we will discuss below.

… or a Filtration Unit

A filtration system is a standalone exhaust unit that draws air from the laser’s work area via ducting and passes it through a filter that captures harmful particles. These units are much more mobile than other exhaust setups, so if you plan on traveling with your laser, or moving it around frequently, a filtration system may be the right choice for you. If you are able to vent outdoors, you will not need this option, but if you plan on using a portable filter unit, your regional or local Epilog distributor can recommend a manufacturer and model.

Optional Accessories

Depending on what laser system you choose, we have a selection of accessories available. These accessories expand the capabilities of your machine and open the doors to new production opportunities. A selection of popular accessories is outlined below.

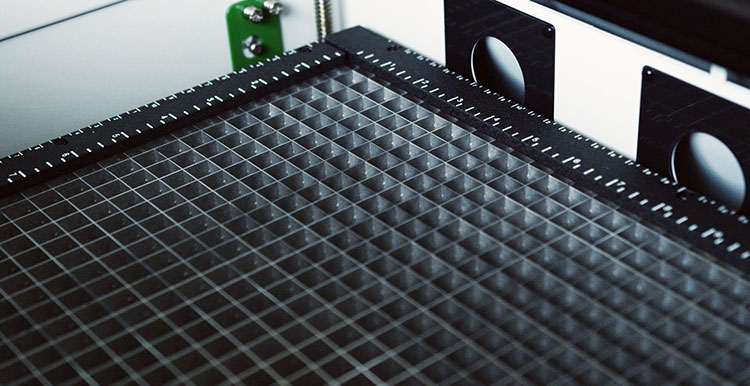

Vector Cutting Grid

Epilog Laser machines come standard with an engraving table. If you’ll be cutting with the laser, you’ll want to make sure you have a vector cutting grid as well. The design of the cutting grid minimizes the amount of work table surface area that is in contact with your material. This reduces residue buildup and minimizes flashback that can result from the laser slicing through your material then meeting a flat surface on the other side. You should use a vector cutting grid when laser cutting, as it will provide you with cleaner and safer cuts.

Air Assist Compressor

This is a popular feature that blows a constant stream of air at the point where the laser focuses and burns away material. This reduces possible flare-ups from combustible materials, reducing leftover residue and allowing you to run the laser slower to cut through thicker materials. Some of our machines have built-in air assist compressors, such as the Fusion Pro 48, while others require an external compressor to be attached. We highly recommend an air assist compressor if you are planning on cutting with your laser.

Machines in the Fusion Edge Series have been pre-plumbed for Air Assist so that all you need to do is to attach a small compressor pump to the back of the machine. The pump can either be purchased through your Epilog representative or you can connect your existing compressed air supply to the receptacle at the back of the machine.

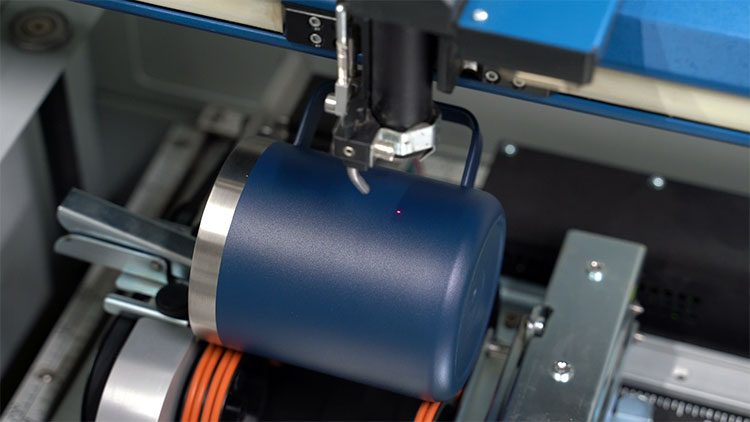

Rotary Attachment

If you want to etch glasses, mugs, wine bottles and other cylindrical objects, you will need a rotary attachment. With a rotary attachment, you place your product onto the rollers, and the laser automatically rotates the object as it engraves, giving you crisp, focused engravings on cylindrical surfaces.

PhotoLaser Plus

PhotoLaser Plus (PLP) is a software package that lets you take your photo engraving to the next level by easily processing photos for engraving on all types of materials. Photo engraving is a highly popular laser application, and PLP can help you create the highest-quality photo engravings in the industry. Check out this video tutorial to see PLP in action.

While the laser machine is the most important tool in establishing your customization services, it’s important to consider what additional components you’ll need – in both the short and long term – that will enhance your setup and ensure your success.

Is it time to incorporate laser engraving and cutting services into your operations? Contact Epilog today to set up a demo so you can see our systems in action!

Phone: +1 303-277-1188

Other FAQ’s

Request More Information

and get more info from your local distributor.