CO2 Metal Marking Spray with a Laser

CO2 laser engravers for marking metal

Metal Marking with a CO2 Laser

CO2 laser machines can directly mark a variety of coated metals such as anodized aluminum or powder coated stainless steel. However, bare metals reflect the wavelength of a CO2 laser, meaning direct marking typically requires a fiber laser source. Fortunately for CO2 laser owners, there’s another great option. Bare metals like titanium or nickel plating can be pre-treated with a metal marking compound prior to engraving with a CO2 laser.

The pre-treatment process is very simple and while it will not actually remove any of the metal material, you will be left with a durable and permanent raised mark on your bare metal products. Operators simply apply the marking solution – some common products include CerMark, Enduramark, and LaserBond – allow it to dry, and then perform the engraving as normal. The heat from the laser bonds the solution to the metal, resulting in a permanent black, silver, or sparkle-type mark from a CO2 laser machine.

Creativity

What can you create?

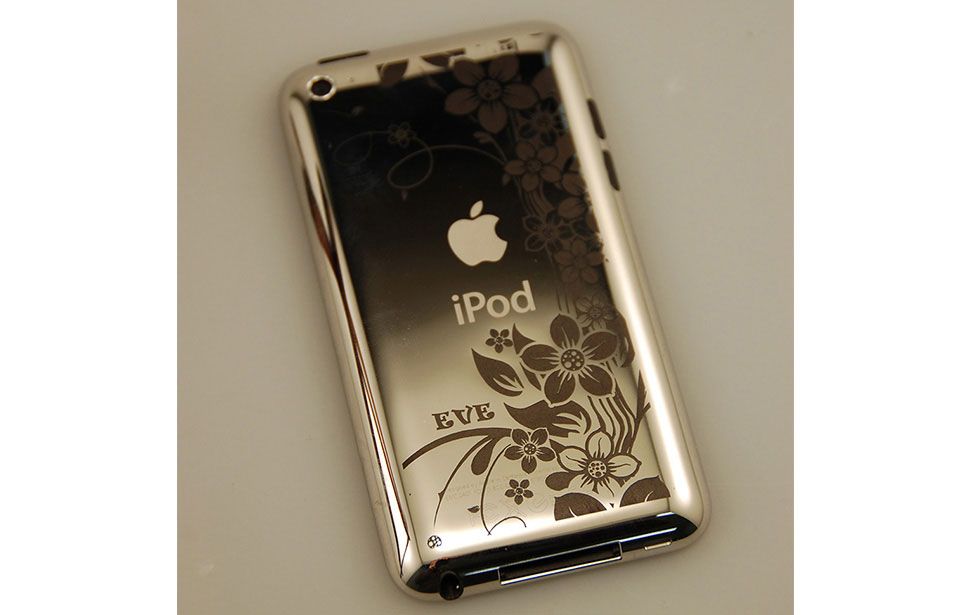

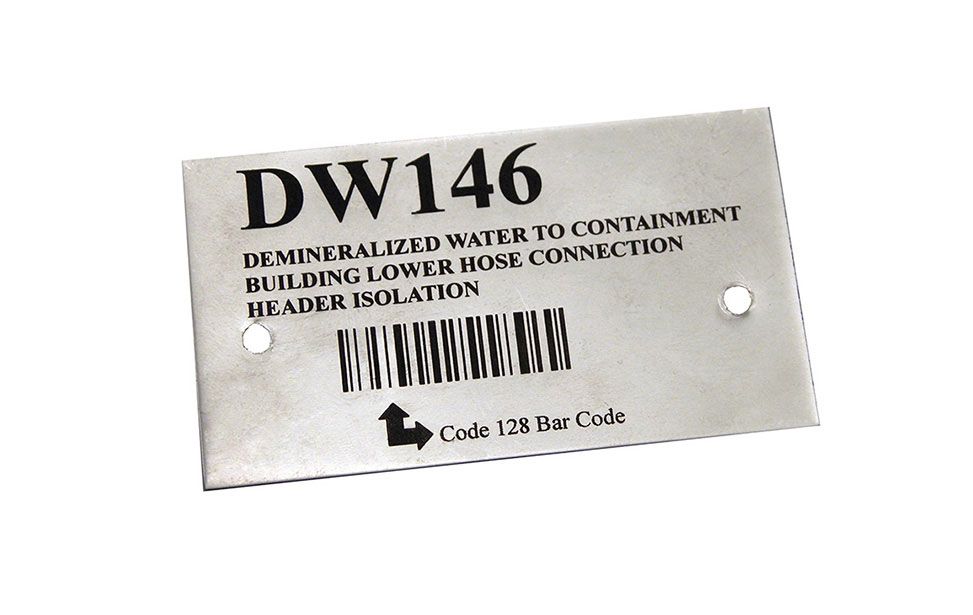

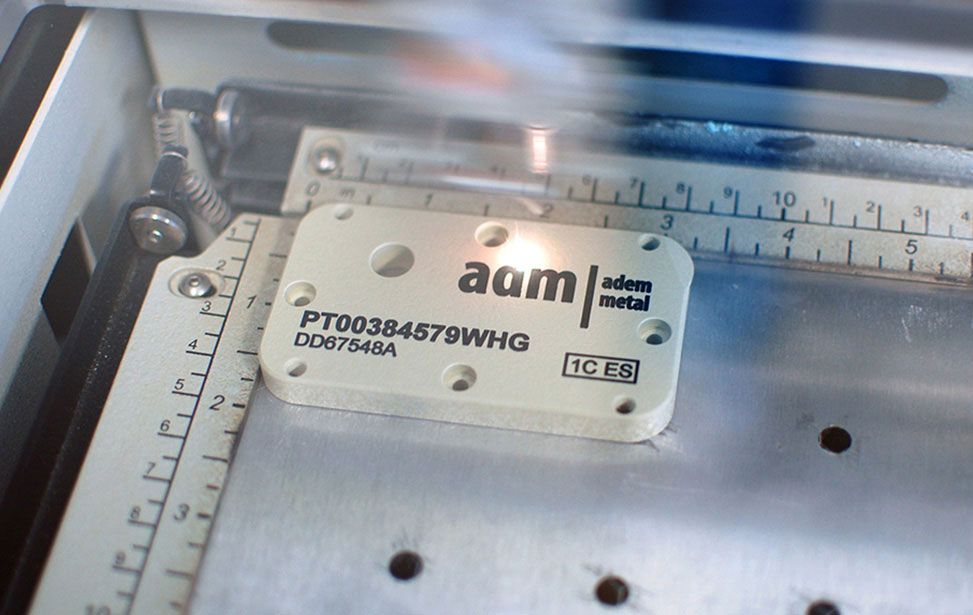

Using a metal marking spray like CerMark, Enduramark, or LaserBond allows laser owners to perform all kinds of exciting (and profitable) applications such as customizing jewelry and pendants, personalizing stainless steel tumblers, or even serializing metal parts/components.

Imagine the Possibilities

The ability to mark metals with a CO2 laser opens the doors to many new projects. From custom water bottles and personalized phones to identification tags and barcodes, metal items are everywhere. Adding an Epilog Laser machine to your toolset lets you take advantage of these opportunities to work on exciting and lucrative endeavors.

Quality Marks with CO2

You don’t need a fiber laser to achieve great quality marks on metal. Pretreating the metal with a special marking agent will allow you to easily mark bare metals with your CO2 laser.

Non-Destructive Marking

Since you’re creating a surface mark, rather than etching into the metal itself, you’re not compromising its structure or impacting the integrity of the material.

Industrial and Creative Applications

Whether you’re applying barcodes to an endless stream of parts or customizing a single flask, metal marking spray and a laser will help you get the job done.

And More…

Engraving is Easy!

Print to your laser from any graphics software

Artwork Setup

Design in your favorite software

Material Settings

Assign speed and power by material

Start Engraving!

Send the job to the laser and press go!

Sample Club

You may also like…

Machine Recommendations

Whether you’re working on individual items or need to manage heavy workloads, an Epilog Laser machine will meet your needs. For reliably and efficiently marking metals, consider these machines, or take a look at our full product line.

-

Fusion Maker 12

Starter SeriesWork Area24″ x 12″

(610 x 305mm)TypeCO2

WattageCO2: 30-40

The newest in Epilog’s laser lineup, the Fusion Maker was designed for the entry-level hobbyist or small business owner. This compact system features up to 60 IPS engraving speeds and our popular IRIS Camera System. -

Fusion Maker 24

Starter SeriesWork Area24″ x 24″

(610 x 610mm)TypeCO2

WattageCO2: 40

Featuring a 24” x 24” engraving table and available in a 40-watt configuration, the Fusion Maker 24 offers users a larger engraving table to tackle bigger projects. -

Fusion Maker 36

Starter SeriesWork Area36″ x 24″

(915 x 610mm)TypeCO2

WattageCO2: 40-50

The largest in the Fusion Maker Laser Series, the Fusion Maker 36 features a 36” x 24” workspace and 40 or 50 watt configuration options. All of the Fusion Maker systems include our IRIS Camera System and 60 inches per second engraving speeds. -

Fusion Edge 12

Business SeriesWork Area24″ x 12″

(610 x 305mm)TypeCO2, Fiber

WattageCO2: 50-60

Fiber: 30Our compact laser system available in several wattage configurations and features up to 120 IPS/3.05 m/s engraving speeds. Also available with a fiber laser source. -

Fusion Edge 24

Business SeriesWork Area24″ x 24″

(610 x 610mm)TypeCO2

WattageCO2: 50-60

A mid-size system that includes Epilog’s IRIS Camera System. -

Fusion Edge 36

Business SeriesWork Area36″ x 24″

(914 x 610mm)TypeCO2

WattageCO2: 60-100

The largest system in the Fusion Edge Series, the Edge 36 offers a 36” x 24” (914 x 610 mm) engraving table and comes in a 60, 80, or 100 watt CO2 configuration. The Edge 36 features 120 IPS/3.05 m/s engraving speeds, and features built-in Ethernet, USB, and Wireless options for networking your laser. -

Fusion Pro 24

Industrial SeriesWork Area24″ x 24″

(610 x 610mm)TypeCO2, Fiber, Dual

WattageCO2: 60-100

Fiber: 30The smallest in our industrial Fusion Pro Laser Series, the Pro 24 is available in 60, 80, or 100 watts and can be configured as a dual-source system with both CO2 and fiber laser capabilities. -

Fusion Pro 36

Industrial SeriesWork Area36″ x 24″

(914 x 610mm)TypeCO2, Dual

WattageCO2: 60-200

Fiber: 30-50Like all systems in the Fusion Pro Laser Series, the Pro 36 includes Epilog’s IRIS Camera System, along with engraving speeds up to 165 inches per second (4.2 m/s). -

Fusion Pro 48

Industrial SeriesWork Area48″ x 36″

(1219 x 914mm)TypeCO2, Dual

WattageCO2: 80-200

Fiber: 50The largest of the Fusion Pros, this industrial system is available in 80, 100, 120, and 200 watt configurations, as a dual-source system, and can be networked via built-in Ethernet, USB or wirelessly.