Laser Engraving Tips and Tricks for Glassware: Master the Art of Etching Glass

A Guide to Laser Engraving Glass with an Epilog Laser Machine

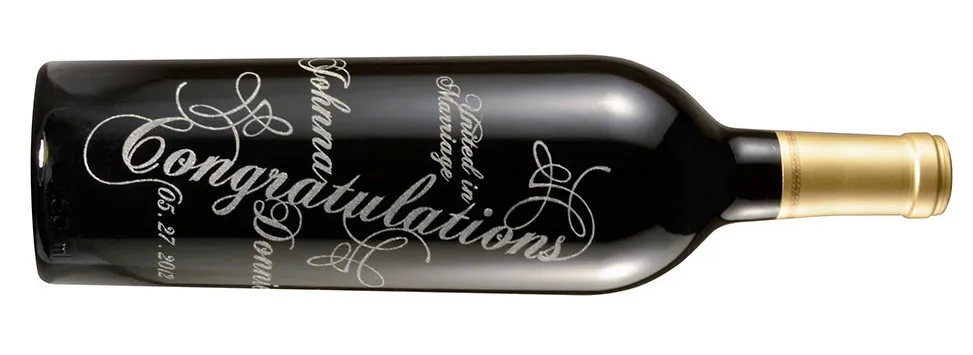

Engraving on glass and crystal can produce stunning results. From engraving the names of the bride and groom on wedding champagne, flutes to etching a company logo on a set of beer mugs and beyond, glass etching and engraving create a sense of sophistication and beauty that is very popular among consumers.

CO2 laser engraving equipment generally offers a quicker and more convenient alternative to traditional glass engraving techniques, such as sandblasting, which necessitates the creation of a template before starting the project. While engraved and etched glassware is in high demand, glass can be a delicate material to work with, depending on the type and lead content.

But don’t let the delicacy of the material dissuade you from glass engraving and etching – just keep the following tips and tricks in mind when working with glass and crystal and you’ll produce the results that keep customers coming back for more.

This guide will explore the benefits of using an Epilog Laser for glass engraving, address common challenges, and provide helpful tips to get the most out of your machine.

Rounded Glass

Rounded glass – like wine glasses, candle holders, beer mugs, etc.- will necessitate a rotary attachment when engraving with a CO2 laser machine. Your rotary attachment should accommodate various shapes and sizes and adjust easily for different lengths, handles, and shapes.

Due to its delicate nature, some users are reluctant to engrave glass. Like most things, you’ll need time, patience and a little practice to increase your proficiency in this craft. But once you’ve established the settings that work well for you, future glass projects can be some of your easiest, most profitable products. Keep these glass engraving tips in mind for your next project to ensure the most elegant and stunning results on this very popular material.

Ready to create stunning glass engravings? Explore our CO2 laser systems and take your designs to the next level.

Why Use an Epilog Laser Machine for Glass Engraving?

Laser engraving isn’t just a more modern method—it provides a range of advantages that traditional approaches, such as hand engraving and sandblasting, simply can’t match. Here’s what sets Epilog Laser machines apart when it comes to engraving glass:

1. Precision and Detail

Epilog Laser machines offer unmatched precision, allowing you to create incredibly intricate designs that might otherwise be impossible with manual methods. From personalized messages and logos to detailed artwork, the clarity and detail you can achieve are second to none.

2. Speed and Efficiency

When running a business or working on multiple projects, efficiency is essential. Laser engraving with Epilog is faster than traditional methods like sandblasting, which means more work is completed in less time. This increased productivity is a game-changer for both hobbyists and professionals.

3. Versatility

Epilog lasers aren’t limited to flat glass surfaces. They can engrave an array of glass types, including curved glass, bottles, jars, and stemware, to name a few. This versatility enables you to work on a variety of projects with ease.

4. Customization

Creating unique and personalized items is easy with Epilog Laser machines. Use their intuitive software to add text, images, or logos to your designs. Customizations are ideal for producing personalized gifts, branded merchandise, or one-of-a-kind artistic creations.

5. Reduced Risk of Breakage

Traditional glass engraving methods often involve physical contact or aggressive processes that can damage the material. Laser engraving, on the other hand, is a non-contact method which minimizes the risk of breakage or chipping during the process.

6. Ease of Use

Despite their professional capabilities, Epilog Laser machines are user-friendly. With intuitive software, clear instructions, and helpful features, anyone from beginners to seasoned makers can easily learn to use them.

7. Professional Results

Consistency is key when creating quality products. With an Epilog Laser, you can achieve consistent, repeatable, and professional-quality engravings every time.

Challenges and Considerations When Engraving Glass with a Laser

While Epilog Laser machines are powerful tools, using them with glass does come with unique challenges. Here are some considerations and tips to ensure your engraving process goes smoothly:

1. Heat Sensitivity

Glass is susceptible to heat, which can cause cracking, chipping, or distortion during engraving. To prevent heat damage:

- Use lower power settings on the laser to reduce the heat applied to the glass.

- Apply a damp paper towel or masking tape to the glass surface to help dissipate heat.

2. Material Variations

Different types of glass (e.g., soda-lime glass, lead crystal) react differently during laser engraving. For instance, lead crystal is more prone to cracking due to its composition. Always test your laser settings on a small area or a sample piece of glass to find the best approach for each material.

3. Focus and Alignment

Precise focus and alignment are critical for clean and consistent engravings. Take the time to properly set the focus of your laser machine, as even slight misalignments can affect the engraving quality.

4. Ventilation

Laser engraving glass produces fine particles and fumes that must be safely removed from the workspace. Proper ventilation or an exhaust system ensures a safe and clean environment.

5. Testing and Refinements to Avoid a Second Pass

Before running any glass engraving job, you must test your speed and power settings on the type of glass you’ll use. Determining the perfect settings will ensure the machine produces the look you want and will help you avoid running the project a second time. Be sure to purchases enough blanks Every project is different. Spend time testing and adjusting the laser’s power, speed, and focus settings to achieve the best results for your specific design and glass type. These refinements will improve overall engraving quality and minimize risks of errors or breakage.

6. Maintaining Optimal Temperatures

An overabundance of heat is the number one cause of broken and fractured glasses. To avoid this, we recommend applying masking material such as a wet paper towel or dish soap to the surface before starting the project. Draping a damp sheet of newspaper or paper towels over the glass before starting a job will significantly reduce the cracks and craters and produce the popular frosted effect on much of the glassware you see today. Coating the glass with a thin layer of ordinary dishwashing detergent also ensures a damp surface to engrave upon. Remember that these moistening agents will dry out eventually – remember to reapply regularly. Ordinary masking tape works well as a heat-deferring material and will produce the frosted effect that is such a hit with consumers.

Tips for Engraving Glass Successfully

Here are some best practices to ensure success when engraving glass with an Epilog Laser machine:

- Use a Rotary Attachment for Round Objects: If you’re working with bottles or curved glass, a rotary attachment stabilizes the object and ensures even engraving.

- Experiment with Designs: Test different design styles and engraving techniques, such as frosting the glass (lightly etching the surface) versus deep engraving for bolder designs.

- Add Color or Paint Fills: To amplify the design’s visibility, apply a colored paint or wax fill into the engraved areas. This is particularly useful for dark or frosted glass.

- Engrave from the Inside: For items like tumblers or jars, consider engraving on the interior surface for a sleek and modern look.

- Clean After Engraving: Use a soft cloth to clean off any residue left behind by the laser beam.

Working with Mirrors – Additional Product Idea

Using the laser engraver with mirrors produces a unique and dramatic effect. If you choose to work with mirrors, remember to perform all the engraving on the reverse side of the glass. Basically, you’ll need to “mirror” or reverse the file you’re working with so that it appears the correct way when looking into the mirror. Also, it’s important to gauge the thickness of the mirror’s coating – when in doubt, it’s best to start with a lower output and increase it as necessary.

Why Choose Epilog Laser for Your Glass Engraving Needs?

Epilog Laser machines not only make laser engraving more efficient but also unlock creative possibilities across a wide range of industries. Whether you’re a small business owner scaling your operations, an artist creating one-of-a-kind pieces, or a crafter looking to personalize gifts, Epilog Laser empowers you to deliver precision, speed, and professional-level results.

With Epilog, you’re not just investing in a laser machine; you’re investing in opportunities to expand your creativity, enhance your craft, and grow your business.

Get Started with Epilog Laser

Are you ready to create jaw-dropping glass designs with an Epilog Laser machine? Whether you’re personalizing gifts, carving intricate details for your artwork, or producing custom pieces for your business, the possibilities are endless.

Contact Epilog’s team today for expert advice, or discover the right machine for your needs. Elevate your engraving game and transform your vision into reality with Epilog Laser. Explore our CO2 laser systems and take your designs to the next level.

Other News

Maximizing Your Epilog Laser Purchase with Section 179

Top 5 Questions to ask your local Epilog Laser Representative

Choosing the Best Laser Engraver for Wood Engraving Projects

Education: How to Pick the Best Laser Machine for Schools

Settings for Success: Expert Tips for Laser Engraving Popular Materials

Laser Engraving Tips and Tricks for Glassware: Master the Art of Etching Glass

Have a story you want to see featured?

Press Contact for Epilog Laser:

Marketing Communications Specialist

About Epilog Laser

Since 1988, Epilog Laser has been designing and manufacturing flying-optics-based CO2 and fiber laser systems that can engrave and cut wood, acrylic, plastic, fabric, rubber and many other materials. Epilog specializes in developing laser systems that create unprecedented marking and cutting quality on all types of products. The company produces versatile and reliable systems that are affordable and easy to use.