Laser Engraving Photos: Tips for Beginners

Photographs are a highly popular choice for laser engraving. By engraving a cherished memory captured in a photo onto a different material like wood or marble, the image is elevated to a unique and lasting keepsake.

In this blog, we’ll cover the basics of photo engraving that will give you a solid foundation for your photo engraving projects.

Practice Makes Perfect

Remember, there’s no single right way to engrave photos. Practice makes perfect, so don’t be discouraged if your initial attempts don’t produce flawless results. The following tips will guide you through the photo engraving process and equip you with the tools to create high-quality, long-lasting engravings.

Materials Matter

A single photograph will be engraved differently from one material to the next. Many users like to use black marble for photo engraving, while others choose black anodized aluminum, black plastic, clear acrylic, or wood for their pictures. Even if you use the same photograph, keep in mind that each material will produce a different engraved look. We recommend testing various materials with the same photo to determine which material creates the look you want.

List of the most popular materials for engraving photos:

- Black Marble

- Black Anodized Aluminum

- Black Plastic

- Clear Cast Acrylic

- Wood

- Glass

Selecting Artwork

Not all photos are ideal for engraving. For optimal laser engraving results, choose photos with a wide range of shades, from light to dark. Photos with large areas of a single color, particularly on wood, often engrave poorly.

Avoid images with expansive backgrounds featuring only one or two small subjects.

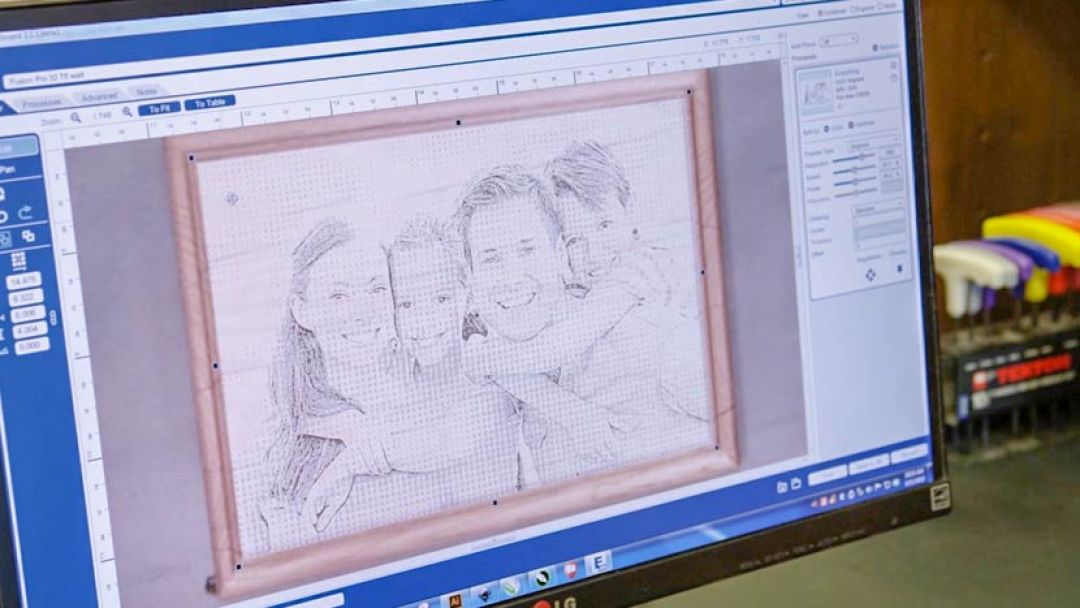

Consider the example photo below. It’s an excellent candidate for laser engraving due to its gradual transition from light to dark shades. It lacks large blocks of a single color and boasts ample detail.

Software Selection

Virtually any graphics software has the ability to modify a scanned or digital photo for engraving purposes. Some software, such as PhotoLaser Plus (Basic) and PhotoLaser Plus (Advanced), include advantageous features that make photo manipulation easier than working solely with your graphics software.

Resolution Reminders

The resolution at which you engrave does not have to be extremely high. Most of the samples we produce are engraved at 200, 300 or 400 DPI. Only occasionally do users need to use a high resolution, such as 600 or 1200 DPI for photo engraving.

Next we’ll cover some tips to ensure you’re engraving optimal photos. Before you start your next photo engraving project ask yourself these questions:

- Does the photo show many gradations of color from light to dark?

- Does the photo show good definition and detail?

- Does the photo have a good contrast and focus?

- Does the photo contain a good number of elements to view?

Whether you’re using high-resolution digital images or scanned images, keep the following tips in mind when acquiring the photograph you wish to engrave:

Scanning Resolution – Scan your photos at a low resolution, such as 200 or 300 DPI. If you are going to engrave your photos at 200 DPI, there really is no reason to scan it in at a higher resolution. Scanning photos in at a lower resolution will also ensure your photos are small enough to work with when manipulating your chosen graphics software.

Choosing Color or Black and White – If you have the option, color is always the way to go with photos. If you’re scanning a photo, you should always scan it in color, even if the photo is black and white (most scanners give you this option.) The color process generates useful data that comes in handy when you go to manipulate the photo.

Digital Downloaded Photos

- Prioritize High Resolution: Always strive for the highest resolution digital image possible when sourcing from the internet.

- Low-Resolution Limitations: Images copied and pasted directly from the internet are often unsuitable for engraving due to their low resolution.

- Finding High-Resolution Images: While high-resolution images exist online, they can be difficult to find. Most internet images are low-resolution and too small for engraving purposes.

Digital Camera Photos

- Modern Camera Advantage: Modern digital cameras typically produce high-resolution images suitable for engraving.

- Older Camera Considerations: Images from older cameras (with resolutions of 2.0 megapixels or lower) may not be of sufficient quality for engraving.

- Camera Phone Limitations: Photos taken with camera phones often lack the high resolution required for producing detailed engravings.”

Size: When obtaining an image for engraving, always aim for the largest size and resolution possible, particularly when scanning physical photographs. Avoid simply stretching the image within your graphics software to increase its dimensions. The process of stretching or expanding the size of the image will significantly reduce the pixel resolution and detail in the image. If the image is stretched excessively, it will become overly pixelated, making it unsuitable for engraving. The effect caused by over-stretching or enlarging a photo has a grainy appearance and can render fine details indistinguishable during engraving. To maintain image quality and ensure a successful engraving, working with the original, high-resolution image whenever possible is crucial.

Whether you’re just beginning to engrave photographs or already familiar with the process, these basic laser tips will help you make the right choices to get the high-quality, professional results you seek.

Other News

Choosing the Best Laser Engraver for Wood Engraving Projects

Education: how to pick the right laser machine

Settings for Success: Expert Tips for Laser Engraving Popular Materials

Laser Engraving Tips and Tricks for Glassware: Master the Art of Etching Glass

How CO2 Laser Machines Can Increase Profits for Your Business

Laser Engraving Photos: Tips for Beginners

Have a story you want to see featured?

Press Contact for Epilog Laser:

Marketing Communications Specialist

About Epilog Laser

Since 1988, Epilog Laser has been designing and manufacturing flying-optics-based CO2 and fiber laser systems that can engrave and cut wood, acrylic, plastic, fabric, rubber and many other materials. Epilog specializes in developing laser systems that create unprecedented marking and cutting quality on all types of products. The company produces versatile and reliable systems that are affordable and easy to use.