Glass (DC) vs. Metal Ceramic (RF) CO2 Laser Tubes

One of the most important considerations when choosing the best CO2 laser system for your application is the decision between glass water-cooled tubes and metal air-cooled laser sources. This is one of the largest differentiators between systems both on price and performance. Here, we’ll take a deep dive into the differences between laser types to help you make the best choice possible.

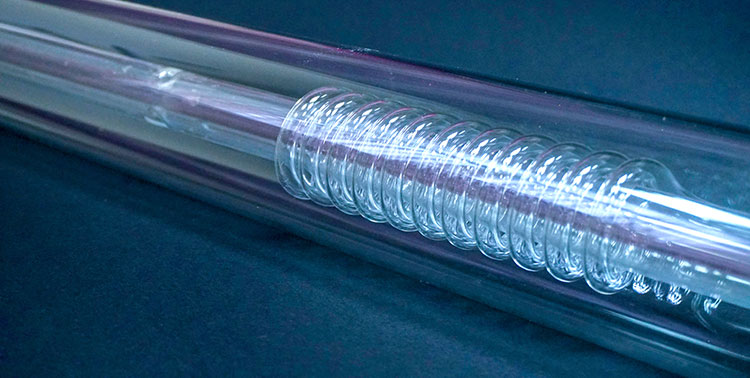

Glass Laser Tubes

Water-cooled glass tubes are often an enticing option, primarily because of their lower cost. Glass tubes themselves cost less, plus their laser is produced by exciting gas with direct current (DC), which is a relatively inexpensive process. Glass tubes also produce good-quality beams that work well for laser cutting. However, glass laser tubes come with several drawbacks.

Cooling

Nearly all glass tubes need to be water-cooled. Glass is a poor thermal conductor, which means circulating water is needed to assist in the removal of heat. Without a water-cooling system, a glass laser tube would overheat and become inoperable. Such a cooling system will increase your cost and your footprint and also introduce more points of failure that need to be maintained.

Performance

The DC-excitation process inherently limits the rate at which the laser tube can pulse. When a laser engraves it doesn’t fire in one continuous burst. Rather, it “pulses” as it moves across the material, firing many times per second. The faster you can pulse the laser tube, the faster you can run the laser system and still get precise engraving.

DC-excited laser tubes pulse less frequently, which significantly reduces engraving speeds and lowers engraving quality. This difference in engraving time can mean a 15-minute job on a metal RF tube system can take over an hour on a similar wattage DC glass tube system.

Operating Temperatures

Glass laser tubes are more sensitive to heat and cold, so if you are storing your system in a warm room without AC, or in a garage without a heater you may not be able to run the machine on hot or cold days.

Serviceability

There are also concerns regarding the lifetime of DC-excited glass tubes. Glass is naturally more fragile than metal, and the risk of damage during shipment and installation is greater. The largest failure concern with glass tubes is that the DC-excitation process bombards a tube’s optics and electrodes with ions, which increases the chance of deterioration over time. Most glass tubes are only backed by 6-month warranties, and when a glass laser tube fails outside that time period, you usually need to purchase a brand-new laser tube, increasing costs and waste.

Metal Laser Tubes

Considered the most industrial of Co2 laser tube design, the only real drawback of metal laser tubes is their higher cost. That cost, though, gives you peace of mind in performance, durability, and safety.

Cooling

Epilog’s metal and ceramic CO2 laser tubes are air-cooled and their gas is excited by radio frequency alternating current (RF). Properly regulating temperature only requires fans, which are built directly into our machines. This not only reduces your spatial footprint, it also removes the need for (and cost of) water cooling equipment, and it limits the number of items that need maintenance. Plus, it avoids the safety concerns presented by water cooling around high voltages.

Performance

The RF-excitement process allows for more rapid laser pulsing, which delivers higher engraving speeds and finer detail in the resulting engravings. Metal tubes are also more durable and last much longer than the glass alternatives. This allows you to complete far more engraving jobs in a day, increasing your profits.

Operating Temperatures

Metal and ceramic laser tubes are less sensitive to heat and cold, allowing you to run your system in a room up to 90 degrees Fahrenheit without voiding your warranty. This increases your choices for where to operate your laser system, even on more extreme temperature days.

Serviceability

RF metal laser tubes, like the ones Epilog uses in our laser systems, are backed by a longer two-year warranties, and are rechargeable, ensuring minimal hassle in the rare event something does go wrong.

Summary of Advantages and Disadvantages of Glass vs Metal CO2 Lasers

(DC) Glass Water-Cooled CO2 Lasers

- Cost-effective: Generally more affordable to produce.

- Reliable for basic engraving: Suitable for many common materials like wood, acrylic, and leather.

- Limited in pulse rate: Using DC electric current to excite the laser results in lower pulse rates, affecting the speed and quality of engraving.

(RF) Metal/Ceramic Air-Cooled CO2 Lasers

- More durable: Metal construction offers better resistance to damage and ambient temperatures.

- Longer lifespan: RF tubes have a much longer operational life.

- Higher pulse rate: Using RF electric current allows for faster and more precise engraving due to higher pulse rates.

- Smaller spot size: RF tubes can produce a smaller laser spot, resulting in finer details and smoother cuts.

Which is Right For Me?

Every situation and budget is unique, and it’s important to research which laser machine, and which laser tube, is the best option for you and your business. With glass laser tubes, you can achieve quality laser cutting at a low price point, while with metal laser tubes, you get both the highest-quality engraving and cutting in a laser source, with much higher throughput of product for increased profits per day.

At Epilog Laser, we build our machines with air-cooled metal and ceramic CO2 laser tubes to provide our customers with the safest, top-performing systems available. For more information and to discuss which laser source is best suited for your specific needs, please fill out this form, and we will be happy to assist you.

Other News

Choosing the Best Laser Engraver for Wood Engraving Projects

Education: how to pick the right laser machine

Settings for Success: Expert Tips for Laser Engraving Popular Materials

Laser Engraving Tips and Tricks for Glassware: Master the Art of Etching Glass

How CO2 Laser Machines Can Increase Profits for Your Business

Laser Engraving Photos: Tips for Beginners

Have a story you want to see featured?

Press Contact for Epilog Laser:

Marketing Communications Specialist

About Epilog Laser

Since 1988, Epilog Laser has been designing and manufacturing flying-optics-based CO2 and fiber laser systems that can engrave and cut wood, acrylic, plastic, fabric, rubber and many other materials. Epilog specializes in developing laser systems that create unprecedented marking and cutting quality on all types of products. The company produces versatile and reliable systems that are affordable and easy to use.