Choosing the Best Laser Engraver for Wood Engraving Projects

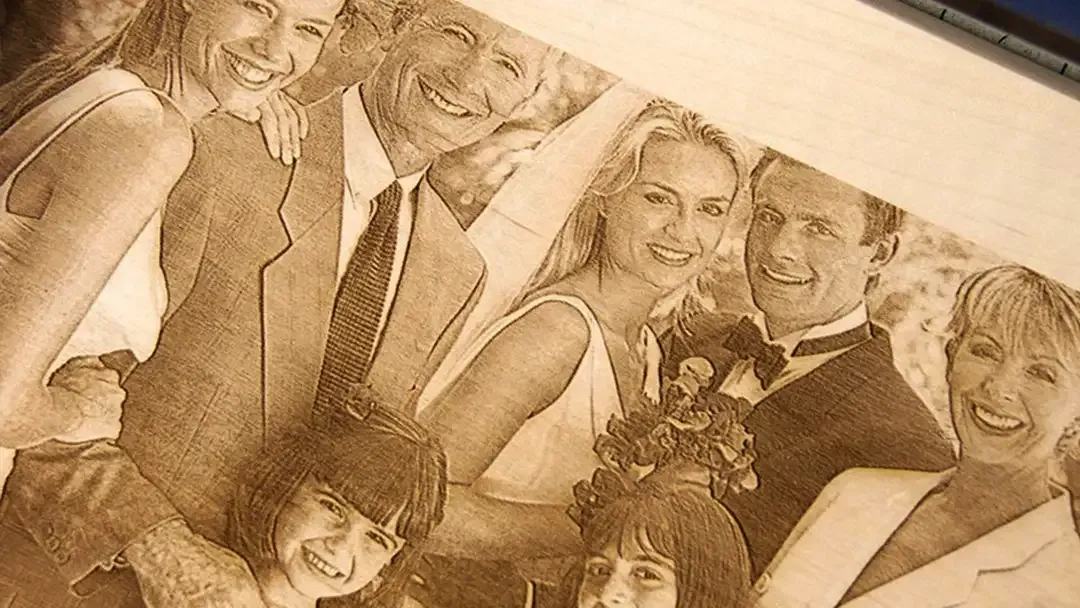

Choosing the optimal laser engraver is paramount for successful wood engraving projects and businesses due to its direct impact on the work’s quality, efficiency, and profitability. A high-quality engraver provides the necessary precision for intricate designs, ensuring clean, sharp lines and consistent results across various wood types. The power and speed of the laser determine the range of projects possible, from delicate engravings to deep cuts, influencing production speed and the ability to handle diverse materials.

A reliable engraving machine minimizes downtime and reduces material waste, crucial factors for maintaining a competitive edge in a business setting. Investing in a superior laser engraver translates to higher-quality products, increased customer satisfaction, and a more successful and sustainable wood engraving business venture. Here’s a guide to help you select the best laser machine for your wood engraving projects.

Understand Your Laser Engraving Needs

Before purchasing a laser engraver, consider your specific needs:

Project Size:

Are you working on small or medium-sized products or large pieces of wood?

The size of the pieces you will be working with can determine the size of the work bed you will need for your machine. A small, hobbyist laser may seem to be the best option due to price, but don’t underestimate your need to scale your operations. A larger work bed will allow you to engrave both smaller items as well as larger pieces that you may work with as your business grows.

Production Volume:

Will you engrave occasionally or for large-scale production?

The throughput of your laser machine is determined by two factors: engraving speed and ability to engrave multiple pieces at one time. Depending on the manufacturer, a more industrial laser machine may run a piece several times faster than the speed of a hobbyist laser. While this may seem unimportant when you are running a single product, as your business grows and your orders are for 100 plus pieces, that speed of engraving can mean the difference of hours or days of engraving time to finish your project.

The ability to fill a larger table with multiple pieces also translates directly into profits. In the example below, a single 16″ x 12″ cutting board takes 2 hours and 40 minutes on a 30-watt 24″ x 12″ system that runs at 60 inches per second. On an 80-watt 48″ x 36″ system that runs at 165 inches per second, you can run the same board in 27 minutes to the same engraving depth.

With an order for 16 cutting boards, that will take 26 hours on the small, lower wattage laser, or less than 3 hours on the higher wattage laser since you can fit 16 boards on a single table. It’s important to consider the time savings and ability to take more engraving job orders as you select the right machine for your needs.

Project Time Study:

16″ x 12″ Cutting Board

| # of Orders | 1 board | 16 boards | |

| 16″ x 12″ 40 watt Hobbyist Laser (6 ips) | 4 hour 20 min | 69 hours 20 min | |

| 24″ x 12″ 30 watt (60 ips) | 30% speed, 100% power | 1 hour 43 min | 27 hours 28 min |

| 48″ x 36″ 80 watt (160 ips) | 70% speed, 100% power | 27 minutes | 2 hours 44 min |

Ability to Engrave Fine Detail: What kind of detail can you achieve on a wood engraving?

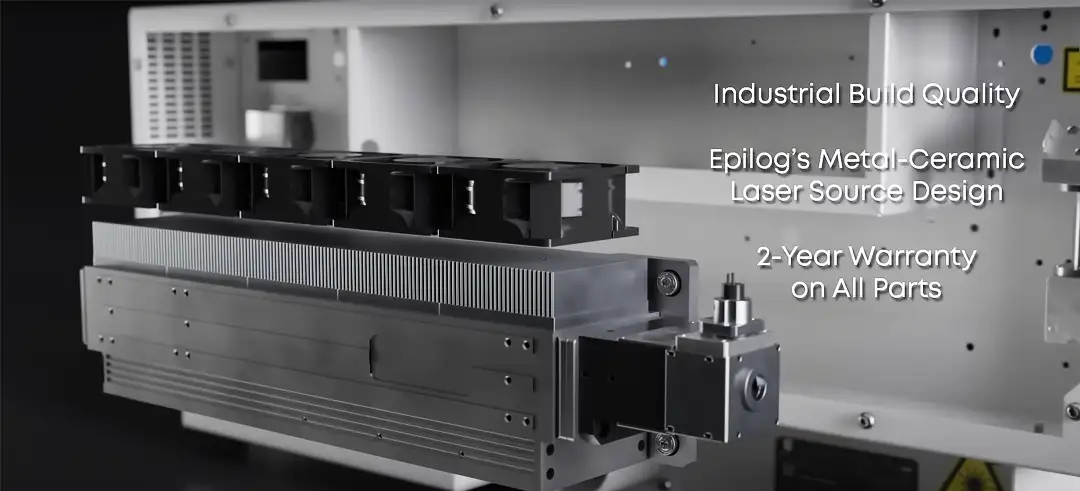

The ability to engrave fine detail on wood is determined by the spot size of the laser. Did you know that a metal/ceramic laser tube’s spot size is as small as .004”? The same size as a single grain of salt! A glass laser tube’s spot size is twice as wide or more, which significantly affects your ability to engrave fine detail on wood. Higher-quality mechanical components, like servo motors, also allow the laser machine to fire the laser at higher speeds while engraving this fine detail, providing you with the highest-quality engraving even at the higher speeds of industrial laser machines.

Key Features to Consider

When selecting a laser engraver, consider the following features:

Power & Wattage

Higher wattage allows for faster engraving and deeper cuts. If you primarily engrave, a 40W–60W laser engraver may be sufficient, but if you plan to cut thicker wood, opt for 75W or higher.

Work Area Size

The size of the engraving bed determines the maximum size of the piece of wood you can engrave. If you need to work with larger materials, choose models with a bigger workspace, like the Fusion Pro series.

Speed & Precision

Higher-end models like the Fusion Pro series offer faster engraving speeds (165 IPS) and high-resolution output, essential for intricate designs.

Software Compatibility

Epilog lasers are compatible with popular design software like Adobe Illustrator, CorelDRAW, and AutoCAD, making them easy to integrate into your workflow.

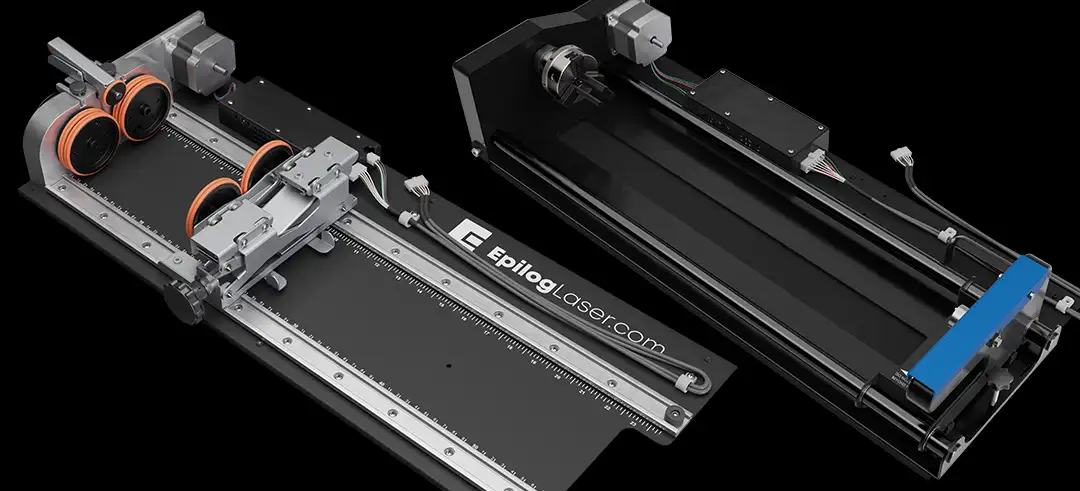

Rotary Attachments

If you plan to engrave cylindrical wooden objects like tumblers or rolling pins, look for models that support rotary attachments.

After-Sales Support & Maintenance

The ability to self-service your laser engraver if you have an issue is key for anyone starting with a laser. A successful laser engraving business cannot afford downtime and Take a close look at the levels of customer support, training, and warranty options you receive with the laser engraver. Ensure that you:

- Understand maintenance requirements (lens cleaning, air assist, etc.)

- Have fast access to technical support and replacement parts.

- Can easily replace parts yourself.

Choosing the Right Laser Series

Epilog offers several laser engraving series, each with unique features. Here’s a breakdown of the most popular ones for wood engraving:

Epilog Fusion Maker – Starter Series – Best for Beginners & Small Projects

- Compact and affordable

- Great for hobbyists and small businesses

- Available in 30, 40, and 50-watt power options

- Ideal for engraving small wooden crafts, plaques, and signs

Epilog Fusion Edge – Business Series – Best for Medium-Sized Businesses

- Faster engraving speeds with high precision

- More workspace than the Fusion Maker series

- Comes in 50, 60, 80, and 100-watt options

- Ideal for detailed wood engravings and light production work

Epilog Fusion Pro – Industrial Series – Best for High-Volume Production

- Large engraving bed (up to 48″ x 36″)

- High-speed performance with precise detailing

- CO2 laser options ranging from 50 to 200 watts

- Great for batch production and large custom wood engravings

Choosing the best laser engraving system for wood engraving depends on your budget, project needs, and production volume. Epilog Laser is one of the most trusted brands in the industry, offering a range of machines tailored to different needs. Beginners and hobbyists may find the Fusion Maker series sufficient, while businesses should consider the Fusion Edge or Fusion Pro series for more efficiency and scalability. Investing in the right machine will ensure high-quality engravings, improved productivity, and long-term success in your woodworking projects.

The best way to determine which laser machine suits your needs is to arrange a demonstration near you. You’ll be able to test your own materials, see how to set up files and run the machine, and ask in-depth questions that will help you make the best decision.

For more information or to schedule an in-person demonstration in your area, fill out this form.

Other News

Choosing the Best Laser Engraver for Wood Engraving Projects

Education: how to pick the right laser machine

Settings for Success: Expert Tips for Laser Engraving Popular Materials

Laser Engraving Tips and Tricks for Glassware: Master the Art of Etching Glass

How CO2 Laser Machines Can Increase Profits for Your Business

Laser Engraving Photos: Tips for Beginners

Have a story you want to see featured?

Press Contact for Epilog Laser:

Marketing Communications Specialist

About Epilog Laser

Since 1988, Epilog Laser has been designing and manufacturing flying-optics-based CO2 and fiber laser systems that can engrave and cut wood, acrylic, plastic, fabric, rubber and many other materials. Epilog specializes in developing laser systems that create unprecedented marking and cutting quality on all types of products. The company produces versatile and reliable systems that are affordable and easy to use.